When the displacement is being blocked, a force is generated.

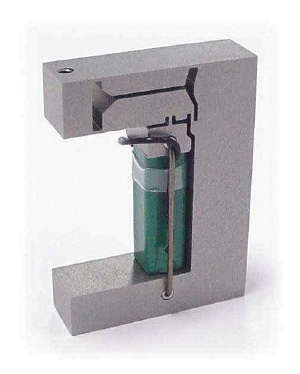

The passive substrate layer in disc piezo actuators is very important. Or they can simply just vibrate at the designed frequency when AC Voltages are applied. Piezo disc actuators, unimorph and bimorph alike, can displace in one direction and/or both directions depending on your applications when DC voltages are applied. Amplifying this deformation is the driving force to generate displacement. One side of the piezoelectric disc expands like a dome, while the other side contracts like a bowl. The center of the piezo ceramic disc deforms the most forming a dome, and direction of displacement depends on how the voltage is applied, in relation to the polarity of the faces of the piezo disc. When voltage is applied to the piezo ceramic disc, the piezoelectric material contracts or expands, deforming the piezo disc actuator and generating displacement. Unsure what you need? Contact us! Piezo Direct is more than happy to work with you to design a custom piezo disc to meet your application requirements.Ī piezoelectric ceramic disc that converts electrical energy to mechanical energy is known as a piezo actuators. Shape, finish, material, dimensions, and performance levels can all be customized! Piezo Direct’s bimorph manufacturing capabilities and piezo discs are suitable for numerous applications. We offer a variety of piezoelectric discs. Piezo discs have the ability to operate in extreme temperatures and environments while yielding high frequency and transient response. Due to their small, thin, lightweight construction, piezo discs are are extremely efficient and consume very little power. As a bimorph with two piezoelectric layers, piezo disc bimorphs greatly magnify the power and range of a piezoelectric actuator, while using very little electrical current.

Piezo discs are widely used as actuators, sensors, and transducers across many industries for endless applications. During the deformation process, a substrate holds the piezoelectric product together and prevents it from falling apart. The substrate acts as a base and stabilizer for the disc actuators and can be any material, conductive or nonconductive. For some special applications, bimorphs do not have a substrate sandwiched in between the two layers of piezo, instead the two pieces of PZT discs are bonded directly to each other. In both unimorphs and bimorphs, the layer(s) of piezo disc material are bonded with a substrate. Metallization is only on the faces of the piezo, not on the side. Piezo discs are metallized, either through a physical or chemical process, and then polarized. They are highly efficient with low power consumption and fast response time. Piezo ceramic discs are small, thin, lightweight, and quiet. When this current is released, the metal springs back to its original state. The most displacement occurs at the center of the piezo ceramic disc, forming a dome or bowl. When a voltage is applied, the piezo disc deforms or contracts, bending the metal with it. Piezo bimorphs are constructed of two active piezo ceramic layers with a passive metal substrate sandwiched in between. Unimorphs deform in a single direction when activated to generate the desired mechanical or electrical output. The faces of the piezo disc are metallized, and the layers are bonded with either a conductive or nonconductive substrate, which acts as a base and stabilizer for the piezo circular disc. Unimorph piezo discs are comprised of one active piezoelectric layer and one non active layer, whereas bimorph piezo discs are comprised of two active piezoelectric layers. Piezoelectric discs can be manufactured in two ways – unimorph and bimorph.

0 kommentar(er)

0 kommentar(er)